In a classroom setting, students will be greatly helped by a well-stocked digital tech library. Learning how to use digital technology in the classroom means that you will need to be able to use computers as well as other technical tools. This will assist students in their job search once they have left the classroom.

Technology can be as simple as a device that allows you to create and print documents using your computer. A touch screen interface makes document production easier than ever. Technology can also be found in the classroom in the form of an interactive whiteboard. These interactive tools are a great way for students to learn from their peers.

One of the most exciting new technologies to hit the market is the cloud. This technology can revolutionize the education sector. Its use will not only make the classroom more effective, it will also make education more accessible. Students will have the opportunity to receive a more personalized educational experience. As an added benefit, the technology will also provide a more secure and reliable learning environment.

In classrooms all over the globe, technology has been shown to increase the quality and quantity of education. The technology makes it easier for students to succeed in their exams and provides them with a higher quality education. The best part? It's completely free. Even though the best schools don't want to use this technology, there are a few community colleges and high schools that are starting to embrace it. These schools are starting to recognize that their students must be prepared for a world where technology will be everywhere.

One of the most important lessons that can be learned is that students deserve more access and rewards for using digital technology. This is especially true for students involved in the clerical industry, as it also applies to those who want to pursue a career in IT.

FAQ

What is the importance of logistics in manufacturing?

Logistics is an integral part of every business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

How can manufacturing prevent production bottlenecks?

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning for capacity requirements as well as quality control measures.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It's all about eliminating variation and creating consistency in work.

What does warehouse refer to?

A warehouse is a place where goods are stored until they are sold. It can be either an indoor or outdoor space. In some cases it could be both indoors and outdoors.

What skills are required to be a production manager?

A production planner must be organized, flexible, and able multitask to succeed. You must also be able to communicate effectively with clients and colleagues.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

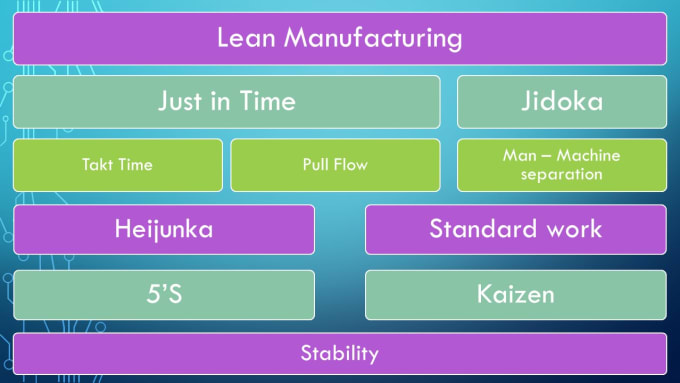

How to Use the 5S to Increase Productivity In Manufacturing

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation created the 5S methodology in 1954. This methodology helps companies improve their work environment to increase efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Workers can be more productive by knowing what to expect.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action to increase efficiency. If you sort items, it makes them easier to find later. When you set items in an order, you put items together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Make sure everything is correctly labeled when you label your containers.

Employees will need to be more critical about their work. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. They will need to develop new skills and techniques in order for the 5S system to be implemented.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They will feel motivated to strive for higher levels of efficiency once they start to see results.