Wichita, just a short drive away from Topeka or Salina, is home to many great things to see and do. You can also do business in Wichita if your company is looking for a new home. CTDI is a great place to find logistics support if that's what you're looking.

CTDI can offer you logistics services. While there are many companies available, it stands out. The company offers a range of services to cable operators and their customers. CTDI provides cost-effective solutions to the communications industry. It also helps improve the efficiency and effectiveness of their logistics operations. CTDI ensures that customers receive their goods in a timely manner and in excellent condition.

CTDI's Wichita facility, Kansas is located at 3434 North Comotara Street. Other facilities are available in the United States as well as at 47 locations in Canada or China. The company employs only a small number of people but the company is growing as they start to serve markets like Tulsa and Oklahoma City.

CTDI has been in business for several years, and provides services to some of the largest cable providers in the country. CTDI has a Cisco certified repair facility. They also have impressive facilities in Canada, China and Europe. Their inventory includes a variety of telecommunications products including wireline and wireless telephones as well as cable television sets. Many cable companies use their products including Spectrum Cable, AT&T Time Warner, Verizon, Comcast and Spectrum.

CTDI's recent acquisition of a state-of-the-art distribution center for Cox Communications is one of their most notable accomplishments. This distribution center, which is located in Wichita in Kansas, will be the largest among three Cox centers in the state. The company plans to expand this facility to include a service center. CTDI's Wichita employees will also increase as the center expands.

The company also operates a telecommunications hub in West Chester. This facility has received a number of awards, including being the cheapest carrier in its class by the Transportation Research Board and being the cheapest carrier in its class by state by the Society for Logistics Management. The company also has a slew of other impressive accomplishments, including providing engineering services to the cable industry. The most remarkable feat of the company was its ability provide services to the biggest telecommunications firms in the world.

CTDI's other most impressive accomplishment is its use of the latest and greatest technology to provide the best logistics solutions for its customers. The company also offers equal opportunities for all employees, regardless of gender or race. Additionally, there are many fun and interesting benefits offered by the company, including a health club and free gym.

FAQ

Is automation important in manufacturing?

Automating is not just important for manufacturers, but also for service providers. It enables them to provide services faster and more efficiently. In addition, it helps them reduce costs by reducing human errors and improving productivity.

What is the role of a logistics manager

A logistics manager ensures that all goods are delivered on time and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

Why is logistics important for manufacturing?

Logistics is an integral part of every business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What is the role and responsibility of a Production Planner?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. They make sure that the product and services meet client expectations.

What are the logistics products?

Logistics involves the transportation of goods from point A and point B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

What are manufacturing & logistics?

Manufacturing is the production of goods using raw materials. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

Why automate your factory?

Modern warehouses have become more dependent on automation. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses need to adapt quickly to meet changing needs. They must invest heavily in technology to do this. Automating warehouses has many benefits. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

This makes workers more productive

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

It reduces downtime, and increases uptime

-

You can be sure that high-quality products will arrive on time

-

Eliminates human error

-

Helps ensure compliance with regulations

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma aims to reduce variation in the production's mean value. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If this deviation is too big, you know something needs fixing.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you've understood that, you'll want to identify sources of variation. Also, you will need to identify the sources of variation. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. You could consider random variations if some widgets fall off the assembly lines. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

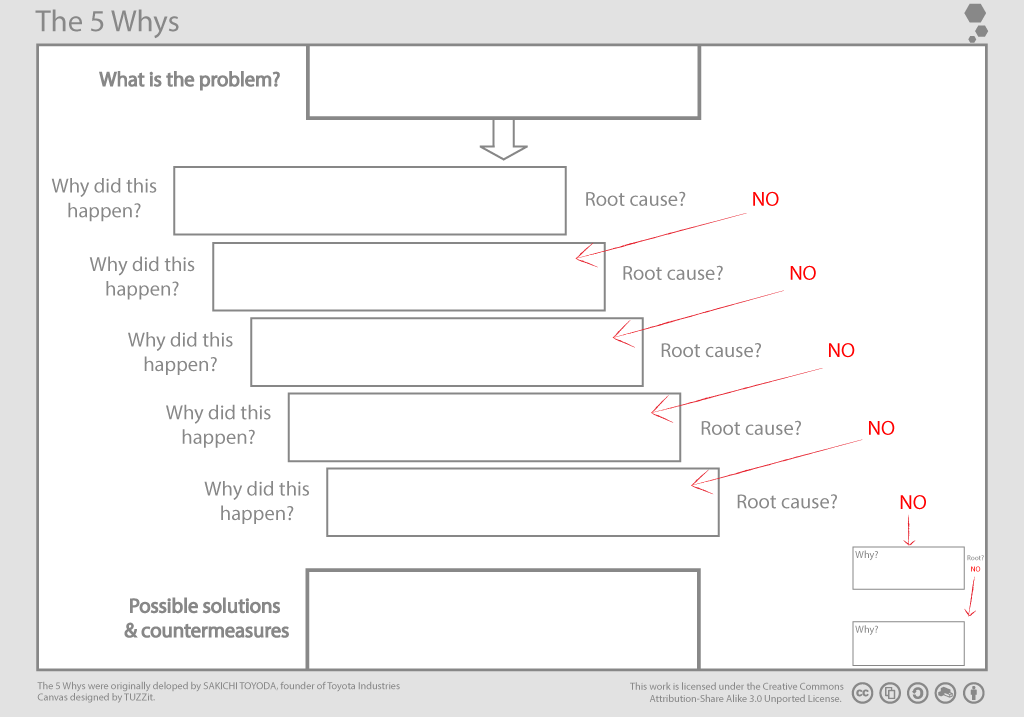

After identifying the problem areas, you will need to devise solutions. The solution could involve changing how you do things, or redesigning your entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they don't work, you will need to go back to the drawing boards and create a new plan.