Manufacturing Phoenix is an Arizona company that provides a range of products to the federal government. It also provides similar products for commercial and individual clients. All production can be done in one location, with all resources located within a few feet of each others. The company also provides employment opportunities for disabled people for over 40 year. The company employs around 70 people in its manufacturing division.

Honeywell Aerospace

The Phoenix area is home to Honeywell Aerospace, an aerospace company that develops innovative transportation solutions. Its products, services, and safety features improve flight safety, increase fuel efficiency, and enhance runway traffic. Nearly every commercial airliner uses its products. In addition, Honeywell Aerospace developed technology that was instrumental in the development of the film 2001: A Space Odyssey. Honeywell Aerospace also manufactures systems for the International Space Station.

Honeywell established a Phoenix-based reactive metal alloy additive manufacturing plant in 2016. This facility converted an old flame spray facility to support production of parts made of titanium and aluminium alloys. By 2017, Honeywell plans to begin producing parts made of Inconel 718 in this facility. The facility was built by Honeywell, which has invested more than $25,000,000.

Raytheon Technologies Corp.

Raytheon Technologies Corp. is a multinational aerospace and defense conglomerate with headquarters in Arlington, Virginia. The company is the world's largest manufacturer of military equipment. Its products include aircraft, rockets, missiles, and more. In addition to being a leading aerospace and defense manufacturer, Raytheon also develops advanced technologies for commercial use.

Raytheon's history is long in the aerospace, defense and military sectors. For example, 27.4% of net sales are made by Raytheon's Aerial Navigation Systems division. It also makes mechanical and electric systems for airplanes.

Benchmark Electronics

Benchmark Electronics, a contract electronics manufacturer company, is located in Tempe Arizona. With more than 13,000 employees around the globe, the Phoenix-based ODM ranks among the top in the world. The company operates offices in Tempe Marketplace, Scottsdale, as well as Tempe Marketplace. Gayla Delly was recently promoted to CEO.

The Phoenix manufacturing facility offers vertically-integrated engineering and manufacturing service. Its capabilities include microwave and RF components, embedded electronics design, and high-frequency circuits. It also provides aftermarket solutions. It serves many customers in the aerospace, defense, and industrial markets.

FAQ

How does a Production Planner differ from a Project Manager?

The difference between a product planner and project manager is that a planer is typically the one who organizes and plans the entire project. A production planner, however, is mostly involved in the planning stages.

Why automate your warehouse

Automation has become increasingly important in modern warehousing. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. They must invest heavily in technology to do this. The benefits of automating warehouses are numerous. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety is boosted

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

This makes workers more productive

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

High quality products delivered on-time

-

Removes human error

-

It ensures compliance with regulations

How can we reduce manufacturing overproduction?

Better inventory management is key to reducing excess production. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. This would allow us to use our resources for more productive tasks.

You can do this by adopting a Kanban method. A Kanban Board is a visual display that tracks work progress. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state represents a different priority level.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. It is possible to keep a task in the beginning stages until it gets to the end.

This allows work to move forward and ensures that no work is missed. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This data allows them adjust their workflow based upon real-time data.

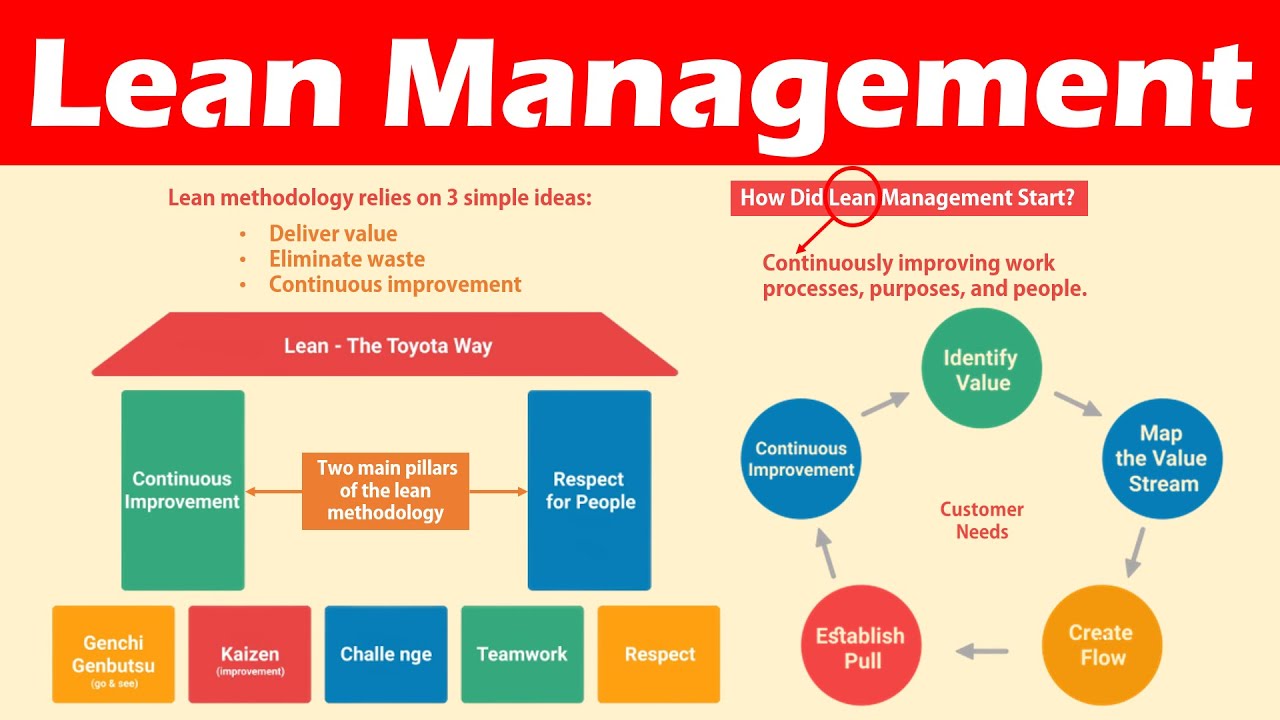

Lean manufacturing is another way to manage inventory levels. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Anything that does nothing to add value to a product is waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

Manufacturers can reduce their costs and improve their efficiency by using these ideas.

What is the job of a logistics manger?

Logistics managers make sure all goods are delivered on schedule and without damage. This is done through his/her expertise and knowledge about the company's product range. He/she should also ensure enough stock is available to meet demand.

Is it necessary to be familiar with Manufacturing Processes before we learn about Logistics.

No. No. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use Six Sigma in Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. Six Sigma seeks to reduce variation between the mean production value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If this deviation is too big, you know something needs fixing.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. You'll also want to determine whether these variations are random or systematic. Random variations are caused by human errors. Systematic variations can be caused by outside factors. If you make widgets and some of them end up on the assembly line, then those are considered random variations. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you have identified the problem, you can design solutions. This could mean changing your approach or redesigning the entire process. You should then test the changes again after they have been implemented. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.