A wide variety of skills are required for railway logistics jobs. Some positions are straightforward to learn. Others require extensive training and years of practice. These types of jobs require a high degree of computer proficiency and product knowledge. Other jobs might involve extensive travel overseas.

A transport logistics specialist helps to understand the logistics industry by coordinating people and materials transportation. The specialist may assess the efficiency of the process and find solutions to specific problems. This may include doing a mechanical check or determining the best routes for a particular cargo.

The rail logistics manager has the responsibility of ensuring that trains, buses and other transport means are in good condition and running on time. They must also ensure that trains follow safety rules and regulations. This job often involves moving freight from one place to another. However, this is only a small part of the job.

Intermodal dispatcher is another entry-level position in the industry. This person coordinates the schedules of several drivers and a shipping firm. The person coordinates the schedule of a group of drivers and a shipping company. This position may also include administrative duties.

A railway logistics manager may also choose to work in a private firm or a government agency. These roles offer career development opportunities and a good pay. In general, you can expect to earn around $45,000 per year. These jobs don't require a bachelor’s degree. Despite the high salary, however, the average rail salary is a bit on the low side.

The logistics title you might see are logistics coordinator, logistics analyst or logistics manager. These are all vital positions. Each of these roles has its own merits, but there is a good chance that your skills will be better utilized in one of these roles than in the other.

Logistics managers should be able to negotiate the best rates, terms, and conditions for their companies' transport needs. This requires analyzing the availability and quality of equipment and services, as well as negotiating with other party and analyzing service levels. Additionally, they must be able to apply basic transportation management concepts to improve the efficiency of their company's logistics processes.

The implementation of a high-tech tracking system for shipments to ensure timely delivery may be overseen by a rail logistics manager. A tracking system may be used to alert customers about the current location of a shipment.

An expert in rail logistics may be called upon to offer advice about how to optimize the transport process. If he or she can do that, they will be able to help their company achieve better results in a shorter period of time.

Many of these roles can be learned through on the job training and experience. A rail logistics coordinator, on the other hand, requires a bachelor's degree and years of experience in a related profession.

FAQ

What is the best way to learn about manufacturing?

The best way to learn about manufacturing is through hands-on experience. If that is not possible, you could always read books or view educational videos.

What are the 7 Rs of logistics?

The acronym 7R's of Logistic is an acronym that stands for seven fundamental principles of logistics management. It was developed and published by the International Association of Business Logisticians in 2004 as part of the "Seven Principles of Logistics Management".

The following letters make up the acronym:

-

Responsible - ensure that all actions taken are within legal requirements and are not harmful to others.

-

Reliable - have confidence in the ability to deliver on commitments made.

-

It is reasonable to use resources efficiently and not waste them.

-

Realistic - Consider all aspects of operations, including environmental impact and cost effectiveness.

-

Respectful: Treat others with fairness and equity

-

Resourceful - look for opportunities to save money and increase productivity.

-

Recognizable: Provide customers with value-added service

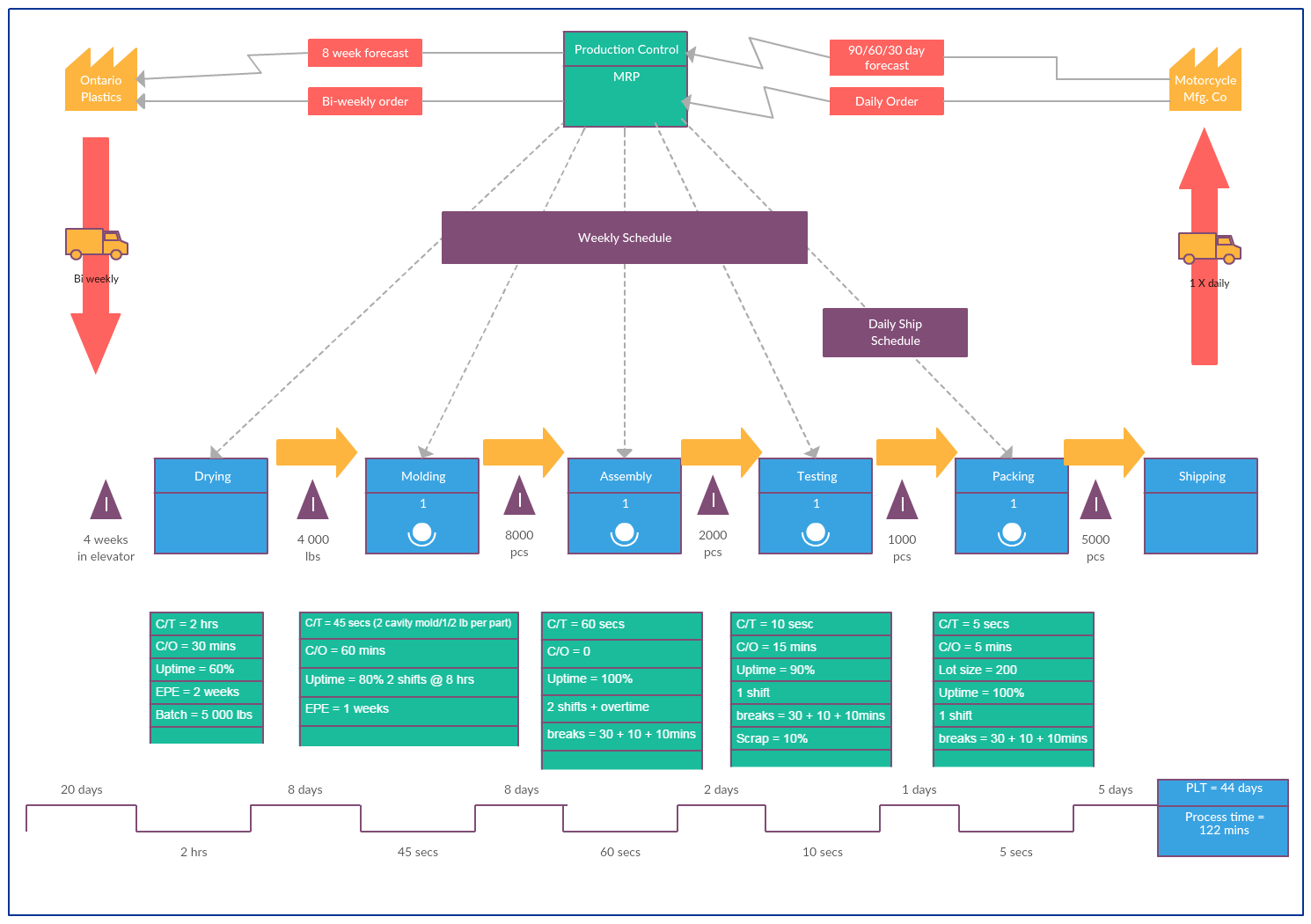

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document will ensure everything is in order and ready to go when you need it. This document should also include information on how to get the best result on set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

The first step is to outline what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

Once you have found the right vehicle, you can think about adding accessories. Do you need people sitting in the front seats? You might also need someone to help you get around the back. Maybe you want to change the interior color from black to white? These questions will help guide you in determining the ideal look and feel for your car. The type of shots that you are looking for is another thing to consider. Will you be filming close-ups or wide angles? Perhaps you want to show the engine or the steering wheel? This will allow you to determine the type of car you want.

Once you have made all the necessary decisions, you can start to create a schedule. The schedule will show you when to begin shooting and when to stop. You will need to know when you have to be there, what time you have to leave and when your return home. Everyone knows exactly what they should do and when. Hire extra staff by booking them ahead of time. It's not worth paying someone to show up if you haven't told him.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects take only a few days while others can last several weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Multiplying takes in the same area will result both in increased costs and a longer time. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Budget setting is an important part of production planning. You will be able to manage your resources if you have a realistic budget. You can always lower the budget if you encounter unexpected problems. You shouldn't underestimate the amount you'll spend. Underestimating the cost will result in less money after you have paid for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

What is the importance of automation in manufacturing?

Automation is essential for both manufacturers and service providers. They can provide services more quickly and efficiently thanks to automation. It also helps to reduce costs and improve productivity.

What are the goods of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that the right product reaches the right place at the right time and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

Why is logistics important in manufacturing?

Logistics is an integral part of every business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics plays a significant role in reducing cost and increasing efficiency.

What does the term manufacturing industries mean?

Manufacturing Industries are businesses that produce products for sale. The people who buy these products are called consumers. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. These companies produce goods using raw materials and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. The basic idea behind Six Sigma is to improve quality by improving processes through standardization and eliminating defects. Many companies have adopted Six Sigma in recent years because they believe that there are no perfect products and services. The main goal of Six Sigma is to reduce variation from the mean value of production. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If this deviation is too big, you know something needs fixing.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. It is important to identify whether the variations are random or systemic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. Random variations would include, for example, the failure of some widgets to fall from the assembly line. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you identify the problem areas, it is time to create solutions. That solution might involve changing the way you do things or redesigning the process altogether. Test them again once you've implemented the changes. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.