Minnesota has many manufacturing jobs. You've come to the right spot if you are searching for them. This article will give you a detailed overview of the state's manufacturing opportunities, including their salary potential and career outlook. You will need to sign up for social media in order to get started. Follow companies and associations relevant to your field by joining LinkedIn. This site allows you to build a network that can relay information about future projects and jobs. You can also follow Strom MN on LinkedIn.

Minnesota manufacturing jobs overview

Minnesota's manufacturing industry offers many jobs and higher median wages. The sector has had some issues in recent times, especially in Southwest Minnesota. Manufacturing jobs have dropped by approximately 28% since 1987. The overall decline in the sector isn't as severe as the U.S. industry average. Manufacturing employment has increased over the past few years, but at a slower rate that the average.

There are encouraging signs that the Minnesota manufacturing industry is on the horizon. Manufacturing remains the state's largest private sector industry, but the number of young workers choosing the manufacturing industry for a career is decreasing. Recent Job Vacancy Studies show that Minnesota has more 11,100 manufacturing jobs today than the 2,563 in 2001. To maintain a competitive edge in today's labor market, manufacturers must attract and keep talented workers.

Minnesota manufacturing workers' career outlook

Minnesota is experiencing record levels of job vacancies. This has negative consequences for state employers. The Minnesota Department of Employment and Economic Development tracks the Greater Minnesota employment market. It is predicted that the number of vacant positions will remain high even after the COVID-19 epidemic has ended. DEED claims that the next generation is more diverse than the previous generations. This means that manufacturers will need to continue to support youth. Minnesota's population will grow by 61.4% between 2018 and 2038 with a slight decline in white residents.

Manufacturing jobs in the state are relatively strong because it is a sector that exports products to other states. Manufacturing jobs are vital for the state's economic health, however the outlook for 2014 is less bright. The state saw an increase of 1.7 percent in jobs in 2013, which was more than the national growth rate at 1.6 percent. According to the Federal Reserve Bank of Minnesota, there will be 1.2 percent growth in job creation in 2014. This would translate into 33,000 new jobs. The results of the recent Fed survey show that the state is at a seven-year high in terms of optimism, as well as hiring in December.

Minnesota's manufacturing workers have the opportunity to make a living.

Minnesota is home to nearly half of the Fortune 500 companies. These include 3M. Medtronic. General Mills. Land O'Lakes. Hormel Foods. And the Minnesota Manufacturing Association. TAACCCT grants have enabled the creation of training programs for adults that equip them with the skills and training required to succeed in advanced production. Earning potential for manufacturing workers in Minnesota is about $23 per hour, which is more than double the average salary of other industries in the state.

Although the Minnesota average wage for a factory worker is $7.305, it can vary depending on the location, skills level, years of experience, and other factors. Because of the lack of factory workers, it is difficult to find a job in this field. Minnesota is 19th out of the 19 states that provide decent wages for factory workers. ZipRecruiter allows you to search for active jobs and find a job that pays higher than the average.

FAQ

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. This is done through forecasting demand and identifying production capacities.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

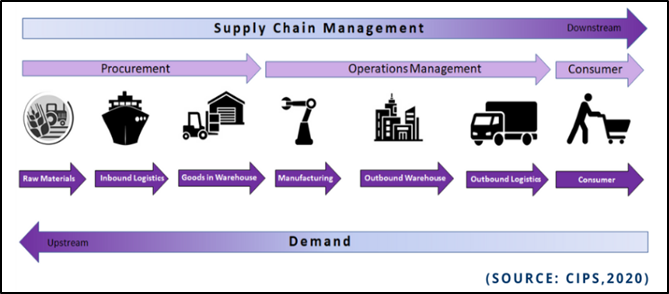

Why is logistics important in manufacturing?

Logistics are an essential part of any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics play a key role in reducing expenses and increasing efficiency.

What are the 7 R's of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was created by the International Association of Business Logisticians and published in 2004 under its "Seven Principles of Logistics Management".

The acronym is made up of the following letters:

-

Responsible - to ensure that all actions are within the legal requirements and are not detrimental to others.

-

Reliable – have faith in your ability and capability to keep promises.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic – consider all aspects of operations, from cost-effectiveness to environmental impact.

-

Respectful - Treat people fairly and equitably

-

Responsive - Look for ways to save time and increase productivity.

-

Recognizable - Provide value-added services to customers

Is it possible to automate certain parts of manufacturing

Yes! Since ancient times, automation has been in existence. The Egyptians discovered the wheel thousands and years ago. To help us build assembly lines, we now have robots.

There are many applications for robotics in manufacturing today. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that make products

Manufacturing could also benefit from automation in other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

How does a production planner differ from a project manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

What type of jobs is there in logistics

There are many types of jobs in logistics. These are some of the jobs available in logistics:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents - They purchase goods and services needed for company operations.

-

Customer service representatives – They answer emails and phone calls from customers.

-

Ship clerks - They issue bills and process shipping orders.

-

Order fillers - They fill orders based on what is ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

How does manufacturing avoid bottlenecks in production?

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes planning to meet capacity requirements and quality control.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma is a management method that helps to improve quality and reduce waste.

It is focused on creating consistency and eliminating variation in your work.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. Six Sigma aims to reduce variation in the production's mean value. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you have this understanding, you will need to identify sources and causes of variation. Also, you will need to identify the sources of variation. Random variations happen when people make errors; systematic variations are caused externally. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you've identified the problem areas you need to find solutions. The solution could involve changing how you do things, or redesigning your entire process. After implementing the new changes, you should test them again to see if they worked. If they don't work, you will need to go back to the drawing boards and create a new plan.