Developing cutting edge manufacturing technologies is one of the primary aims of the National Network for Manufacturing Innovation. President Obama announced the interagency initiative in his FY 2013 budget proposal. It aims to unite federal agencies, community colleges, and university engineering schools in order for innovative manufacturing technologies to be commercialized.

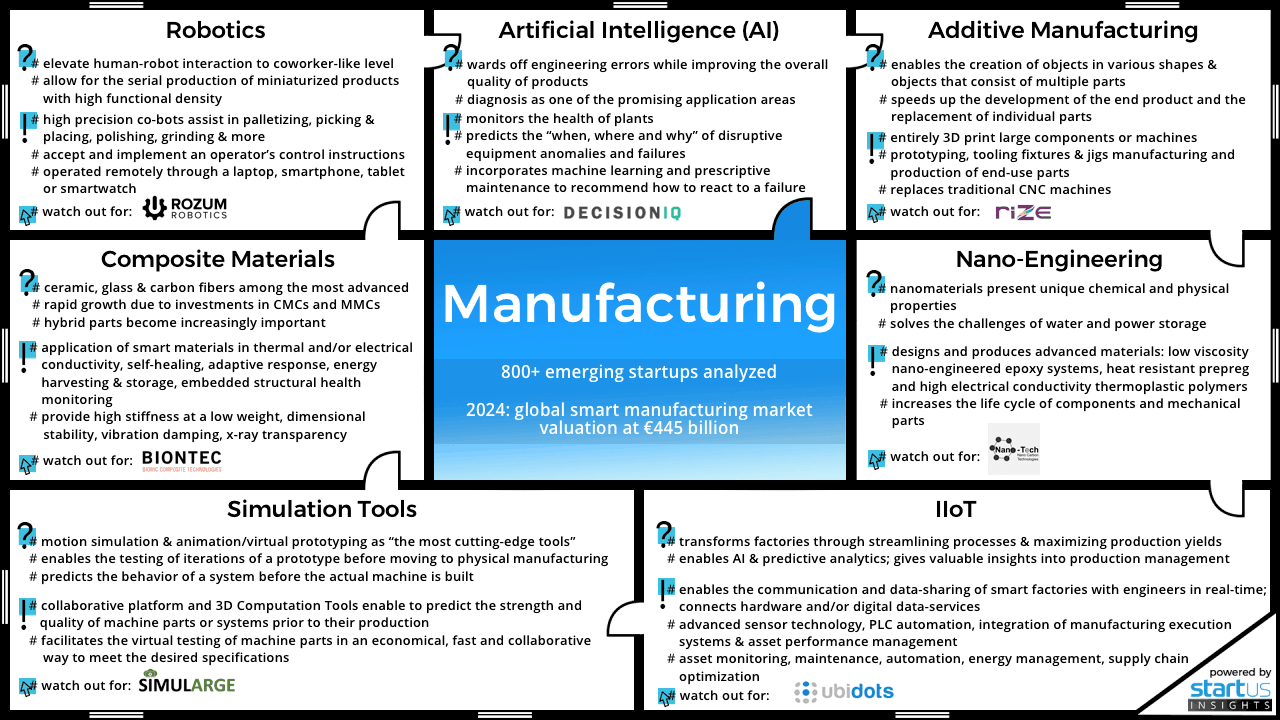

The United States plays a key role in its economy, with manufacturing being a major sector. American workers find good work in this sector. In order to remain competitive, manufacturing companies are investing in technological innovations that help them stay productive while reducing labor costs. These innovations include automation and green energy sources. Companies invest in machine-downtime solutions. This includes new products such as autonomous mobile robotics that lower labor costs and increase productivity. In addition, companies are investing in technologies that reduce resource wastage, such as smart sensors.

The "Maker's Economy," which is expected to transform the manufacturing process, will be revolutionizing how products are made. This is an economy where manufacturing users are actively involved in designing and building new products. The manufacturing sector is expected to take advantage of these innovations to boost productivity, improve operational efficiency, and enhance decision-making. It is also expected it to be a major contributor in the nation's overall production. The United States has been a leader in manufacturing for many years.

The "Maker's Economy" is built on a range of technologies including smart factories, artificial intelligence, and other intelligent systems. These innovations improve manufacturing productivity by increasing worker efficiency and decreasing the amount of time it takes to produce a product. The Industrial Internet of Things, or IIoT, uses sensors and data as a guide for tasks. It also monitors industrial assets continuously. The IIoT also requires secure connectivity and fast data transmission. It is also expected that it will increase warehouse efficiency and supply chain visibility.

The National Network for Manufacturing Innovation (NNNMI) will be composed of at minimum fifteen manufacturing institutes. This network is expected to assist in the rapid development of new manufacturing technologies. The network will also include public/private partnership from both government entities and private businesses.

There are currently 14 manufacturing innovation institutes in the United States, with another three institutes expected to be funded by the Commerce Department in May 2013. Two Institutes are expected to be funded in part by the National Institute of Standards and Technology. This will provide a total of up to $70 million per institute over five to seven years.

Each Institute for Manufacturing Innovation (IMI) will have a different research focus. They will act as innovation centers for the state and local economies. These Institutes will be able to assist manufacturers with their integration efforts. These institutes provide access to cutting-edge technology and equipment, as well training opportunities. These institutes can also be used to help manufacturers tackle cross-cutting problems in advanced manufacturing.

The Network for Manufacturing Innovation serves a variety of purposes, including the acceleration of the commercialization of innovative manufacturing technology, bridging gaps between laboratory research and market applications, as well as strengthening state economies and local economies. The institutes will be operated by the U.S. Department of Energy (DOE), and the program will be funded through the U.S. Commerce Department's National Institute of Standards and Technology.

FAQ

How important is automation in manufacturing?

Automating is not just important for manufacturers, but also for service providers. They can provide services more quickly and efficiently thanks to automation. It helps them to lower costs by reducing human errors, and improving productivity.

What is production management?

Production Planning refers to the development of a plan for every aspect of production. This document will ensure everything is in order and ready to go when you need it. You should also have information to ensure the best possible results on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

The first step in filming is to define what you want. You may have decided where to shoot or even specific locations you want to use. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

Once you have found the right car, you can start thinking about extras. You might need to have people in the front seats. Or perhaps you need someone walking around the back of the car? You may want to change the interior's color from black or white. These questions will help guide you in determining the ideal look and feel for your car. Another thing you can do is think about what type of shots are desired. What type of shots will you choose? Maybe you want to show the engine and the steering wheel. These things will help you to identify the car that you are looking for.

Once you have established all the details, you can create a schedule. You can use a schedule to determine when and where you need it to be shot. The schedule will show you when to get there, what time to leave, and when to return home. So everyone is clear about what they need to do. It is possible to make arrangements in advance for additional staff if you are looking to hire. It's not worth paying someone to show up if you haven't told him.

Also, consider how many days you will be filming your schedule. Some projects only take one or two days, while others may last weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Multiple takes at the same place will result in higher costs and longer completion times. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Another important aspect of production planning is setting budgets. Setting a realistic budget is essential as it will allow you to work within your means. It is possible to reduce the budget at any time if you experience unexpected problems. It is important to not overestimate how much you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning can be a complex process. However, once you know how everything works together it will become easier to plan future projects.

What are the responsibilities for a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should also be aware and responsive to any company problems.

They must also be able to communicate with sales and marketing departments.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

Why automate your warehouse

Modern warehousing is becoming more automated. Increased demand for efficient and faster delivery has resulted in a rise in e-commerce.

Warehouses should be able adapt quickly to new needs. They must invest heavily in technology to do this. The benefits of automating warehouses are numerous. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

This makes workers more productive

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

It reduces downtime, and increases uptime

-

High quality products delivered on-time

-

Removes human error

-

This helps to ensure compliance with regulations

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma's primary goal is to reduce variation from the average value of production. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If it is too large, it means that there are problems.

Understanding how variability works in your company is the first step to Six Sigma. Once you've understood that, you'll want to identify sources of variation. Also, you will need to identify the sources of variation. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

After identifying the problem areas, you will need to devise solutions. The solution could involve changing how you do things, or redesigning your entire process. After implementing the new changes, you should test them again to see if they worked. If they don't work you need to rework them and come up a better plan.