Materials engineers create, design, and test new materials in order to develop tomorrow's technologies. Materials engineers work with metals and ceramics to develop materials that meet chemical, electrical and mechanical requirements.

What does a materials engineer do?

Material engineers develop, test, and process raw materials for products that include aircraft wings, computers chips, biomedical equipment, or even golf clubs. These engineers analyze and assess the structures and properties in metals. ceramics, plastics. nanomaterials.

The specific materials and industries in which a materials engineer works will determine the responsibilities they have. The responsibilities of a materials engineer vary depending on the type of material they work with and the industry in which they work.

What is the role of a materials scientist engineer?

A materials scientist engineer is a person who works with various materials such as ceramics, metals and composites in order to make these materials stronger, lighter and more durable. A materials science engineer can create new materials or improve on existing ones.

What is a Materials Engineer?

For a career as a materials engineer you will need to have a bachelor’s degree in an engineering or materials science field. This degree should include classroom and laboratory work with an emphasis on engineering principles. This program may take a couple of years to complete.

After graduation, you can look for a job in materials engineering and earn around PS25,000 per year. Your salary will rise significantly as you gain experience.

How to become materials engineer

The qualifications that you need to become a materials engineer differ between industries and employers. Most jobs do require a Bachelor's Degree in Materials Science or Engineering. It will also include a study of mathematics, physics and chemistry.

A materials science engineer's qualifications are usually a high school diploma, and a bachelor degree in an appropriate field like physics or chemistry. Higher-level research positions usually require a doctoral or master's level degree.

What is the average salary for a materials scientist?

Salary ranges for materials engineers are dependent on their level and expertise as well as the type of industry they work in. You can also expect bonuses and other benefits for your work.

What is the career future for material engineers?

Materials engineering is expected to have a very bright future, with many new opportunities for those who wish to enter this field of work. This is because of the increasing demand for newer, more advanced materials in fields such as medicine, architecture and communication.

Studying metallurgy or chemistry can lead to a career as a materials engineer. This will help you gain the knowledge and skills you need to begin a new career. A degree in an area such as Chemistry will improve your skills for research and innovation. For additional experience, it is possible to work in a company that specializes in a certain field of materials.

FAQ

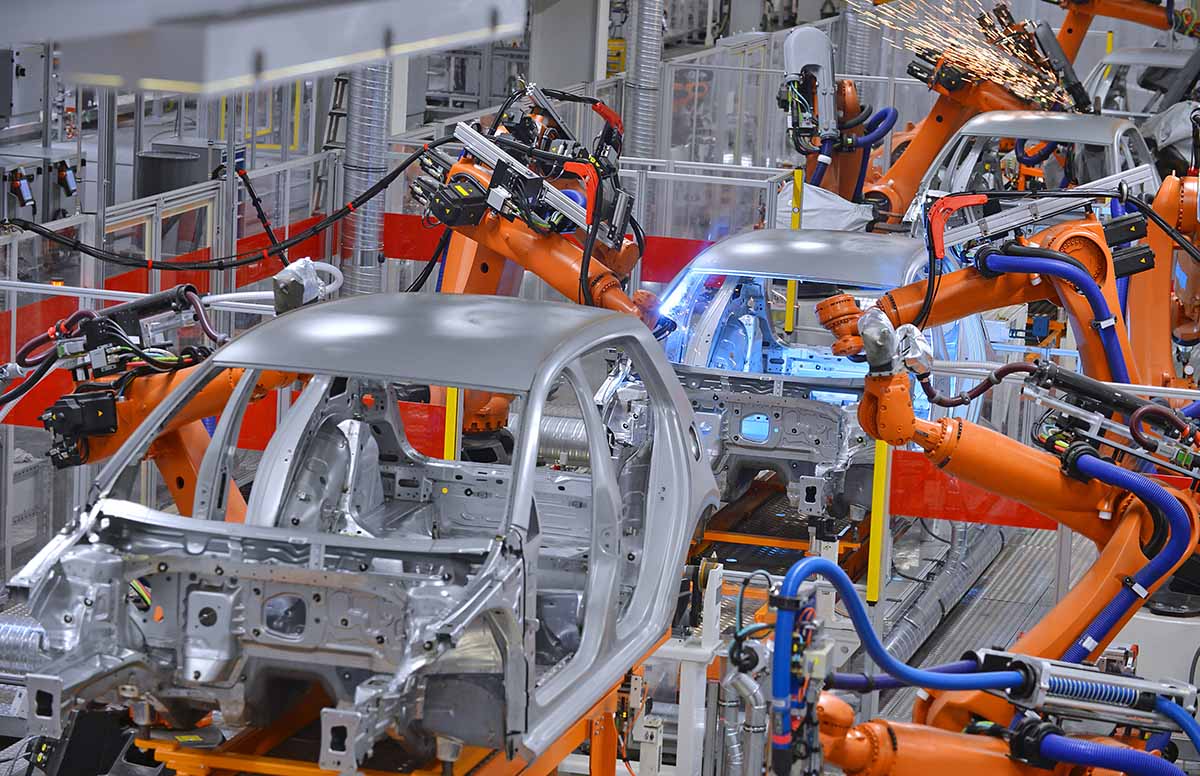

How important is automation in manufacturing?

Automation is important not only for manufacturers but also for service providers. It allows them provide faster and more efficient services. It also helps to reduce costs and improve productivity.

What is the role and responsibility of a Production Planner?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They also ensure the quality of the product and service meets the client's requirements.

What jobs are available in logistics?

Logistics can offer many different jobs. Here are some examples:

-

Warehouse workers: They load and unload trucks, pallets, and other cargo.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service representatives – They answer emails and phone calls from customers.

-

Ship clerks - They issue bills and process shipping orders.

-

Order fillers - These people fill orders based on what has been ordered.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

What's the difference between Production Planning & Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. This can be done by forecasting demand and identifying production capabilities.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

Why automate your warehouse

Modern warehousing is becoming more automated. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses should be able adapt quickly to new needs. They must invest heavily in technology to do this. Automating warehouses has many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety is boosted

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

Increases efficiency of workers

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

You can be sure that high-quality products will arrive on time

-

Eliminates human error

-

Helps ensure compliance with regulations

What is production plan?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. This document is designed to make sure everything is ready for when you're ready to shoot. This document should include information about how to achieve the best results on-set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to decide what you want. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. You might decide you need a car, but not sure what make or model. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

Once you have found the right vehicle, you can think about adding accessories. Do you need people sitting in the front seats? Perhaps you have someone who needs to be able to walk around the back of your car. You may want to change the interior's color from black or white. These questions will help you determine the exact look and feel of your car. The type of shots that you are looking for is another thing to consider. Will you be filming close-ups or wide angles? Maybe you want to show your engine or the steering wheel. This will allow you to determine the type of car you want.

Once you've determined the above, it is time to start creating a calendar. You can create a schedule that will outline when you must start and finish your shoots. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. It will help everyone know exactly what they have to do and when. Book extra staff ahead of time if you need them. There is no point in hiring someone who won't turn up because you didn't let him know.

Also, consider how many days you will be filming your schedule. Some projects take only a few days while others can last several weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Shooting multiple takes over the same location will increase costs and take longer to complete. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Budget setting is another important aspect in production planning. You will be able to manage your resources if you have a realistic budget. It is possible to reduce the budget at any time if you experience unexpected problems. You shouldn't underestimate the amount you'll spend. You'll end up with less money after paying for other things if the cost is underestimated.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely used in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses are now using lean manufacturing to improve their competitiveness. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three types of lean manufacturing.

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous improvement refers to continuous improvement of processes as well people and tools.