Global supply-chain Management is the term used to describe the distribution of goods and/or services across a transnational company's global network. The principle behind this concept is to maximize profit, while minimizing waste. There are many benefits to this method of distribution, but it is not without its drawbacks. Let's take a look at some of the issues. You can read on to find out more about the advantages of global supply-chain management. We'll also talk about some of its challenges.

Resilience

A strategy that fosters resilience is key to being a global supply chain manager. Redesigning the supply chain, eliminating redundant workers, and implementing multiple sources can all help to increase the supply chain's resilience. Although supply chains may seem rigid in the short term they can become more resilient with constant vigilance. Cin7 is one inventory management software provider that offers various educational materials.

Information sharing

Although the role information sharing plays in global supply chains management may seem vague, it is crucial to the survival companies. This study examines how information can be shared to benefit all parties involved in a supply chain. Information sharing offers many benefits, which may vary depending on the type of information. The value of information will vary depending on who is involved. Below are some examples of types of information that can benefit a supply chain.

Quality management

Quality issues are an important part of any supply chains. It is crucial for companies to ensure product quality. However it is equally important that secondary issues are addressed and supply chain risk managed. This article will address the role of quality in global supply chain management. It will also show how current business systems can fail this challenge. Let's discuss how companies can overcome this challenge and implement more effective quality control practices.

Logistics links

As consumer preferences and needs continue to change, so does the business's. The global supply chain is a complex web of suppliers, individuals, and companies that works together to deliver goods on time and to the right place. Logistics plays a crucial role in global supply chains management. This helps companies to reduce costs and improve performance. The supply chain includes vendors, producers and warehouses as well as transportation companies, distribution centers and retailers.

Pandemic COVID-19

Global supply chain management is urgently needed due to the large-scale spread of COVID-19. To respond to emergencies, global supply chains are critical. They ensure that essential supplies are available in a timely manner. Other issues have strained the global supply chains, such as China's ongoing lockdown and economic uncertainty. This pandemic has been a test for supply chain resilience, flexibility and adaptability. Companies will be evaluated not only on how they respond to this crisis but also on the corporate values that they display.

The economic impact

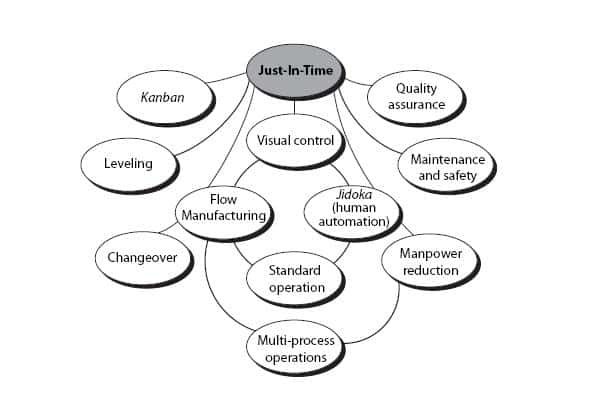

Global supply chain management is vital for the global economy. Manufacturers are becoming more dependent on one source of vital supplies as they switch to JIT (just in time) production. JIT production models come with a major drawback. They make it more difficult for companies to disrupt their supply chains. According to a recent survey, almost half of executives plan on removing some production from China while one-third intend to de-emphasize JIT Manufacturing.

You have many career options

Global supply chain management oversees all aspects of an organization's international procurement strategy. They work closely with suppliers and coordinate inventory logistics to ensure high-quality goods. They are responsible for monitoring and analysing data related to supply chain performance. This role requires collaboration with many departments within a company. These are just a few career options that people with this type of background can choose from. Each of these career options offer great career opportunities.

FAQ

Why is logistics important in manufacturing?

Logistics are essential to any business. They are essential to any business's success.

Logistics play a key role in reducing expenses and increasing efficiency.

What is the job of a production plan?

Production planners ensure all aspects of the project are delivered within time and budget. They also ensure that the product/service meets the client’s needs.

What are the 7 Rs of logistics?

The acronym 7Rs of Logistics refers to the seven core principles of logistics management. It was created by the International Association of Business Logisticians and published in 2004 under its "Seven Principles of Logistics Management".

The acronym consists of the following letters:

-

Responsible - ensure that actions are in compliance with legal requirements and do not cause harm to others.

-

Reliable - have confidence in the ability to deliver on commitments made.

-

It is reasonable to use resources efficiently and not waste them.

-

Realistic - Consider all aspects of operations, including environmental impact and cost effectiveness.

-

Respectful - treat people fairly and equitably.

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable: Provide customers with value-added service

How can we increase manufacturing efficiency?

First, identify the factors that affect production time. The next step is to identify the most important factors that affect production time. You can start by identifying the most important factors that impact production time. Once you identify them, look for solutions.

What skills are required to be a production manager?

A production planner must be organized, flexible, and able multitask to succeed. Also, you must be able and willing to communicate with clients and coworkers.

Why should you automate your warehouse?

Modern warehouses are increasingly dependent on automation. Increased demand for efficient and faster delivery has resulted in a rise in e-commerce.

Warehouses must be able to quickly adapt to changing demands. They must invest heavily in technology to do this. Automation of warehouses offers many benefits. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

Increases efficiency of workers

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Quality products delivered on time

-

Removes human error

-

Assure compliance with regulations

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands for "Sort", "Set In Order", "Standardize", "Separate" and "Store". Toyota Motor Corporation invented the 5S strategy in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. Workers can be more productive by knowing what to expect.

There are five steps that you need to follow in order to implement 5S. Each step has a different action and leads to higher efficiency. You can make it easy for people to find things later by sorting them. When items are ordered, they are put together. After you have divided your inventory into groups you can store them in easy-to-reach containers. You can also label your containers to ensure everything is properly labeled.

This requires employees to critically evaluate how they work. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. To implement the 5S system, employees must acquire new skills and techniques.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.