Industrial engineers create systems that are efficient and integrate workers with machines, materials, data, and energy in order to provide or make a service. They can work in an office, or in production settings such as a warehouse or manufacturing facility.

Industrial Engineer Entry Level in Texas

You will be responsible for making sure that the production process runs smoothly. Your responsibilities include analyzing problems, troubleshooting issues and implementing changes to improve efficiency. It is possible to also train and support technicians using the systems and equipment designed by you.

The type of company that you work for will determine your job duties. You may be asked by some manufacturers to design a procedure for dealing with hazardous waste. Other companies require that you create a monitoring system and control the flow.

As manufacturers are constantly looking for ways of cutting costs and increasing efficiency, you may be working on projects that reduce waste in the production process. You could reduce the inventory in a storage facility, improve the efficiency of machines or identify and eliminate any wasteful practices.

Work with a company producing transportation equipment or computers and electronics. These are typically full-time positions, with employment expected to grow 10% over the next ten years.

Manufacturing Engineering Jobs Texas

To get your foot into the door of industrial engineering, you should start with a job in a manufacturing plant for heavy machinery or equipment. This is a good way to gain experience in industrial engineering. Many plant managers will look for candidates that have such experience.

During your time at the plant, you will be expected to participate in training programs and seminars. These training sessions will make you a more productive industrial engineer. They may also assign you to do research and refine your skills.

Eastman Manufacturing Engineer

If your skills are the right fit, you may be offered an opportunity to work as an Industrial Engineer at Eastman Chemical Mcallen, Texas. This fast-paced, rewarding job offers you the chance to work for a leading energy and technology company.

As an industrial engineer you will be responsible for maintaining and implementing engineered labor standards at distribution centers all over the country. You will play a vital role in the industrial engineering team. This includes presenting and providing engineering standards to employees at these facilities.

FAQ

Why automate your factory?

Modern warehousing is becoming more automated. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses must adapt quickly to meet changing customer needs. To do so, they must invest heavily in technology. The benefits of automating warehouses are numerous. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

Companies can scale more easily

-

Workers are more productive

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

You can be sure that high-quality products will arrive on time

-

Removing human error

-

Assure compliance with regulations

What are manufacturing and logistics?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

How is a production manager different from a producer planner?

The main difference between a production planner and a project manager is that a project manager is usually the person who plans and organizes the entire project, whereas a production planner is mainly involved in the planning stage of the project.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

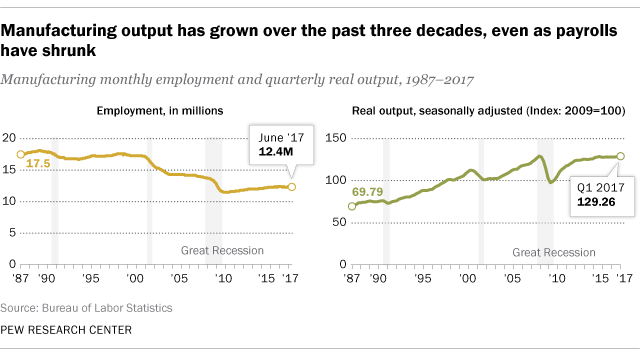

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use the Just In-Time Production Method

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. It's the process of obtaining the right amount and timing of resources when you need them. This means that only what you use is charged to your account. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He noticed that workers were often paid overtime when they had to work late. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. Also, you should look at the whole project from start-to-finish and make sure you have the resources necessary to address any issues. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. You won't have to pay more for unnecessary items.

There are different types of JIT methods:

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will allow for you to track the material that you have left after using it. This will let you know how long it will be to produce more.

-

Inventory-based: This is a type where you stock the materials required for your projects in advance. This allows you to predict how much you can expect to sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based JIT: This type of JIT is most commonly used. Here, you allocate certain resources based on demand. If you have many orders, you will assign more people to manage them. If you don’t have many orders you will assign less people to the work.

-

Cost-based: This approach is very similar to resource-based. However, you don't just care about the number of people you have; you also need to consider how much each person will cost.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT: A variation on resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT is another variant of resource-based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based JIT: One of the most recent forms of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, your goal is to add value to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. This is used to increase production and minimize inventory.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It is essential because it reduces lead-times and increases throughput.