You must make sure that the job description outlines all of the duties required to attract top candidates for transportation and logistics jobs. These duties could range from ordering raw material to filling out company paperwork. It may sound appealing to hire the wrong person, but this can cause the job to be less attractive. This can be a problem for both your business and your customers. You will also need to invest time and money in training the new employee.

Job description

Many industries employ transport and logistics professionals to move people or goods from one point to another. While some work in shipping, others might be involved with road maintenance. The work involves monitoring the safety of products and monitoring traffic congestion. Those who work in this field are often required to adapt to changing business needs and work in various locations.

An effective job description should focus on the required skills and training needed for a particular job. However, it should also reflect the company's culture. It should state whether the job is permanent or temporary.

Salary

You can find a wide range of jobs in transportation and logistics, starting at entry level to more senior positions. The industry you work in and your experience will determine the salary level. An entry-level position usually starts at $40,000 per year. There is still room for advancement, though, as these salaries can increase.

You have many options when it comes to salary for logistics or transportation jobs. Some are more lucrative than some. While entry-level salaries are less than in other fields, if you're a skilled worker, your earnings may be higher. Many companies offer in-house training and even graduate-level education.

Requirements

High-skilled workers in logistics and transportation are highly sought after by many industries. These jobs have a primary focus on ensuring that goods arrive safely, on-time, and at an affordable cost. As a result, it is essential for companies to recruit the right staff with the right skills. Even though junior staff don't need to have any previous training, anyone who wants to be a Supply Chain Practitioner Advanced Apprenticeship should have the relevant qualifications.

A good degree is essential if you plan to work in transportation or logistics. There are plenty of courses available that will help you to develop your knowledge and skills. The Chartered Institute of Logistics and Transport UK has a Level 2 Certificate for Transport and Logistics. This course is great for those just starting out in this field. You can also gain valuable work experience by undertaking a graduate recruitment scheme, which is offered by many large logistics companies.

Locations

Logistics and transport careers are diverse. These careers often require you to plan and assess different distribution methods. These jobs require analytical thinking and the ability of managing complex data. Communication skills are essential. Certain jobs require you to travel far from home. There are many graduate training programs in logistics and transport that will equip you with the skills necessary to be successful in this field. Many of these programs will offer paid internships.

Transport and logistics occupations are in great demand. They are expected to increase by 3% from 2019-2029, the same as the national median. However, some occupations are expected to grow faster than average such as those that require commercial pilots or airline pilots. Driver/sales employees and drivers of delivery trucks are also available in this sector.

FAQ

Do we need to know about Manufacturing Processes before learning about Logistics?

No. You don't have to know about manufacturing processes before learning about logistics. It is important to know about the manufacturing processes in order to understand how logistics works.

What skills is required for a production planner?

Being a production planner is not easy. You need to be organized and flexible. Also, you must be able and willing to communicate with clients and coworkers.

What does the term manufacturing industries mean?

Manufacturing Industries are companies that manufacture products. Consumers are people who purchase these goods. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They create goods from raw materials, using machines and various other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

What is the best way to learn about manufacturing?

Experience is the best way for you to learn about manufacturing. But if that is not possible you can always read books and watch educational videos.

What is production planning?

Production Planning refers to the development of a plan for every aspect of production. This document is designed to make sure everything is ready for when you're ready to shoot. This document should also include information on how to get the best result on set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

It is important to first outline the type of film you would like to make. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you've found the perfect car, it's time to start thinking about adding extras. What about additional seating? Or perhaps you need someone walking around the back of the car? Maybe you want to change the interior color from black to white? These questions will help you determine the exact look and feel of your car. Another thing you can do is think about what type of shots are desired. What type of shots will you choose? Perhaps you want to show the engine or the steering wheel? These factors will help you determine which car style you want to film.

Once you have all the information, you are ready to create a plan. A schedule will tell you when you need to start shooting and when you need to finish. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. This way, everyone knows what they need to do and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. You don't want to hire someone who won't show up because he didn't know.

Also, consider how many days you will be filming your schedule. Some projects may only take a couple of days, while others could last for weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Multiple takes of the same location will lead to higher costs and take more time. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budget setting is another important aspect in production planning. It is important to set a realistic budget so you can work within your budget. Keep in mind that you can always reduce your budget if you face unexpected difficulties. However, you shouldn't overestimate the amount of money you will spend. You'll end up with less money after paying for other things if the cost is underestimated.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

What are the essential elements of running a logistics firm?

You need to have a lot of knowledge and skills to manage a successful logistic business. Effective communication skills are necessary to work with suppliers and clients. You need to understand how to analyze data and draw conclusions from it. You will need to be able handle pressure well and work in stressful situations. To improve efficiency, you must be innovative and creative. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

How can we reduce manufacturing overproduction?

Better inventory management is key to reducing excess production. This would reduce the time needed to manage inventory. This will allow us to free up resources for more productive tasks.

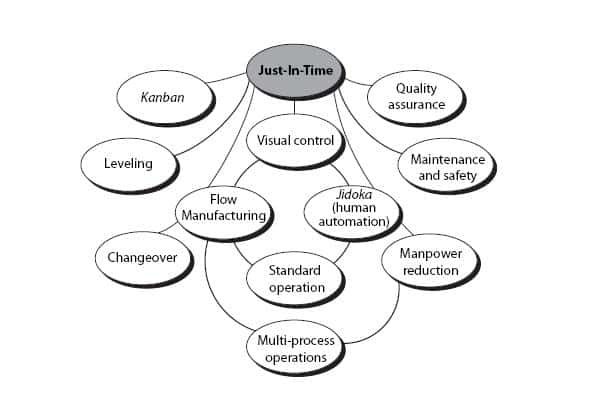

This can be done by using a Kanban system. A Kanban Board is a visual display that tracks work progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents a different priority level.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. It is possible to keep a task in the beginning stages until it gets to the end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. Managers can view the Kanban board to see how much work they have done. This allows them the ability to adjust their workflow using real-time data.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that doesn't add value to the product is considered waste. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". The 5S methodology was developed at Toyota Motor Corporation in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. These actions allow workers to perform their job more efficiently, knowing what to expect.

Implementing 5S requires five steps. These are Sort, Set In Order, Standardize. Separate. And Store. Each step requires a different action, which increases efficiency. For example, when you sort things, you make them easy to find later. When you arrange items, you place them together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Labeling your containers will ensure that everything is correctly labeled.

Employees must be able to critically examine their work practices. Employees need to be able understand their motivations and discover alternative ways to do them. To implement the 5S system, employees must acquire new skills and techniques.

The 5S method not only increases efficiency but also boosts morale and teamwork. They are more motivated to achieve higher efficiency levels as they start to see improvement.