Integrated supply chain management allows companies to optimize and monitor the performance of their supply chains. This creates a responsive, streamlined production network. The more responsive and streamlined your supply chain, the more efficient your operations. Integrated supply chain management is a great way to increase your profits, and decrease waste. This allows you to produce products that are better quality, reliable, and cheaper.

Integrated supply chain management can improve your order reliability. Your production schedule and inventory levels will be better managed, which will allow you to be more responsive. Also, your delivery schedule will work more efficiently. An integrated supply chain also improves your risk management. It can also lower greenhouse gases emissions. This can help you meet your environmental goals.

Drafting a contract with preferred vendors is the first step to integration. These agreements should reflect your company's unique needs. The agreement should contain information about your production schedule, materials required, and costs. You should also be able show how your preferred suppliers will benefit you organization. You may also find lower prices by purchasing a greater number of goods and services.

Having a solid understanding of your connections, and how they affect your business, is an important component of integrated supply chain management. This will help you identify opportunities to improve performance and prevent mistakes. Also, you need a complete end-to–end plan in place to meet all of your needs. This plan should be flexible enough for any production differences. This will also help to avoid delays.

Just-in–time distribution is an excellent example of an integral supply chain. This strategy helps to decrease operational costs and reduce warehouse space requirements. It can also allow for accurate forecasting. An integrated supply chain is important to reduce greenhouse gas emissions. This is possible by reducing your dependence on large fixed assets.

Vertical integration is when all elements of a product are in place. This could be a manufacturer or vendor. This could provide a manufacturer with a greater share in profits. You may also consider buying a manufacturer of widgets or a business that makes widgets. This can help you control your competitor's business, and allow you to set a fair price on widgets.

A container management strategy is another example of integrated supply chain. This allows you view your inventory and make adjustments to container pull strategies as required. It also allows you to make changes to your production schedule in real time.

If you can clearly see your goals, a supply chain management plan will be more efficient. The main objective of an integrated supply chain is to optimize performance and provide the best possible products for your customers. You can reduce plastic waste by using an integrated supply network. This can help you to improve your profit margins and reduce your greenhouse gas emissions.

FAQ

Why is logistics so important in manufacturing?

Logistics is an integral part of every business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics are also important in reducing costs and improving efficiency.

How can overproduction in manufacturing be reduced?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. This could help us free up our time for other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban Board is a visual display that tracks work progress. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state represents an individual priority level.

When work is completed, it can be transferred to the next stage. It is possible to keep a task in the beginning stages until it gets to the end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This information allows them to adjust their workflow based on real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing emphasizes eliminating waste in all phases of production. Any product that isn't adding value can be considered waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Packaging not required

-

Overstock materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What are the responsibilities of a logistic manager?

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is done by using his/her experience and knowledge of the company's products. He/she should make sure that enough stock is on hand to meet the demands.

What are the products and services of logistics?

Logistics refers to the movement of goods from one place to another.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What is manufacturing and logistics?

Manufacturing refers to the process of making goods using raw materials and machines. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

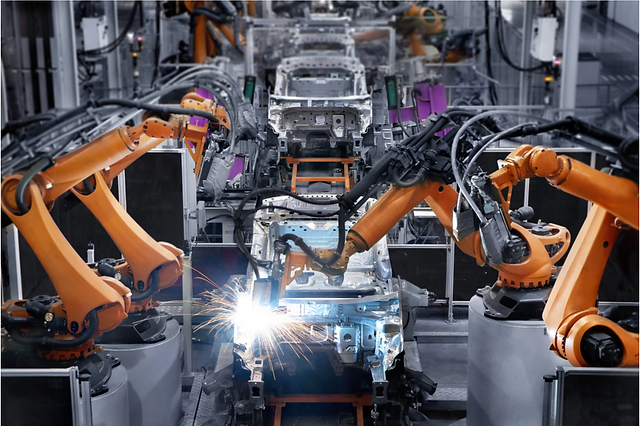

Why automate your factory?

Modern warehouses have become more dependent on automation. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses have to be flexible to meet changing requirements. Technology investment is necessary to enable warehouses to respond quickly to changing demands. Automating warehouses is a great way to save money. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety enhancements

-

Eliminates bottlenecks

-

Allows companies scale more easily

-

It makes workers more efficient

-

This gives you visibility into what happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

You can be sure that high-quality products will arrive on time

-

Eliminates human error

-

This helps to ensure compliance with regulations

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

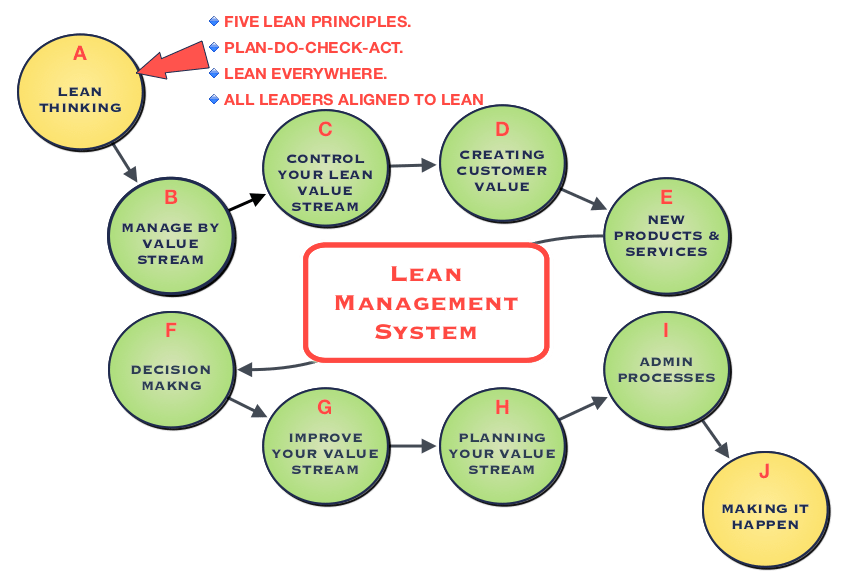

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes the elimination of defects and waste throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Many industries worldwide use lean manufacturing. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Lean manufacturing includes five basic principles:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many businesses have adopted lean production techniques to make them more competitive. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

It can be applied to any aspect of an organisation. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types in lean manufacturing

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.