A well-functioning supply chain can positively impact all aspects of an organization. Included in this are customer satisfaction, cost-reduction and business expansion. Supply chain management is important for any size business.

Supply chains are often neglected, but they have a huge impact on your business's performance. If your supply chain is organized, there will be fewer delays and fewer costly material shortages.

Successful supply-chain management increases consumer satisfaction as well by delivering products and quantities at the perfect time. It increases profits and boosts your company's reputation.

The supply chain has been a focus of companies for many years. They have always tried to lower costs and improve speed. They have invested heavily into new technologies, infrastructure, and processes.

Numerous studies have shown how a firm's capability to manage the supply chain can impact its performance both financially and in terms of operations. They determine whether the business can run efficiently and meet customer requirements.

They can save costs when they have good training and an understanding of how the whole business works. They can increase profits, improve customer satisfaction and build better supplier relationships by working closely with all stakeholders throughout the supply chain.

In a world where markets are moving quickly and product cycles are shorter, it is critical to be able adjust quickly. It means analyzing and managing raw inventory, transit times, and supplier lead times in real time. The numbers have to be accurate and meaningful.

Supply chain managers need to understand how a missed delivery can affect the bottom line. A supply chain manager must also plan for backups.

They will be able to overcome unexpected challenges with these backup plans. They will also give them a competitive advantage over their rivals that lack flexible supply chains.

An effective and well-organized supply network is crucial to the success of any business. This ensures that the correct products are delivered to consumers at the right time, which fulfills their requirements and increases their loyalty.

It is very important to consider the different stages of a product's life cycle when deciding how to best align your supply chain with the manufacturing network and distribution system. Creating the optimal supply chain will help you meet the unique requirements of each product, regardless of its type or stage.

A good supply-chain strategy will make sure that the organisation is "fit for purpose" and can change from being flexible and responsive to efficient, low-cost and innovation driven.

The organizational design of the Supply Chain function interacts and supports its business strategy through assets, technology, process, and people. When these elements are not aligned, execution can be challenging and a company's supply chain may fail to deliver on its promises.

FAQ

Why is logistics important for manufacturing?

Logistics is an integral part of every business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics are also important in reducing costs and improving efficiency.

What does manufacturing mean?

Manufacturing Industries are companies that manufacture products. These products are sold to consumers. This is accomplished by using a variety of processes, including production, distribution and retailing. They create goods from raw materials, using machines and various other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

What are the logistics products?

Logistics involves the transportation of goods from point A and point B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

Why automate your factory?

Modern warehouses are increasingly dependent on automation. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses have to be flexible to meet changing requirements. To do so, they must invest heavily in technology. Automating warehouses is a great way to save money. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety increases

-

Eliminates bottlenecks

-

Companies can scale more easily

-

Increases efficiency of workers

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

You can be sure that high-quality products will arrive on time

-

Eliminates human error

-

It helps ensure compliance with regulations

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

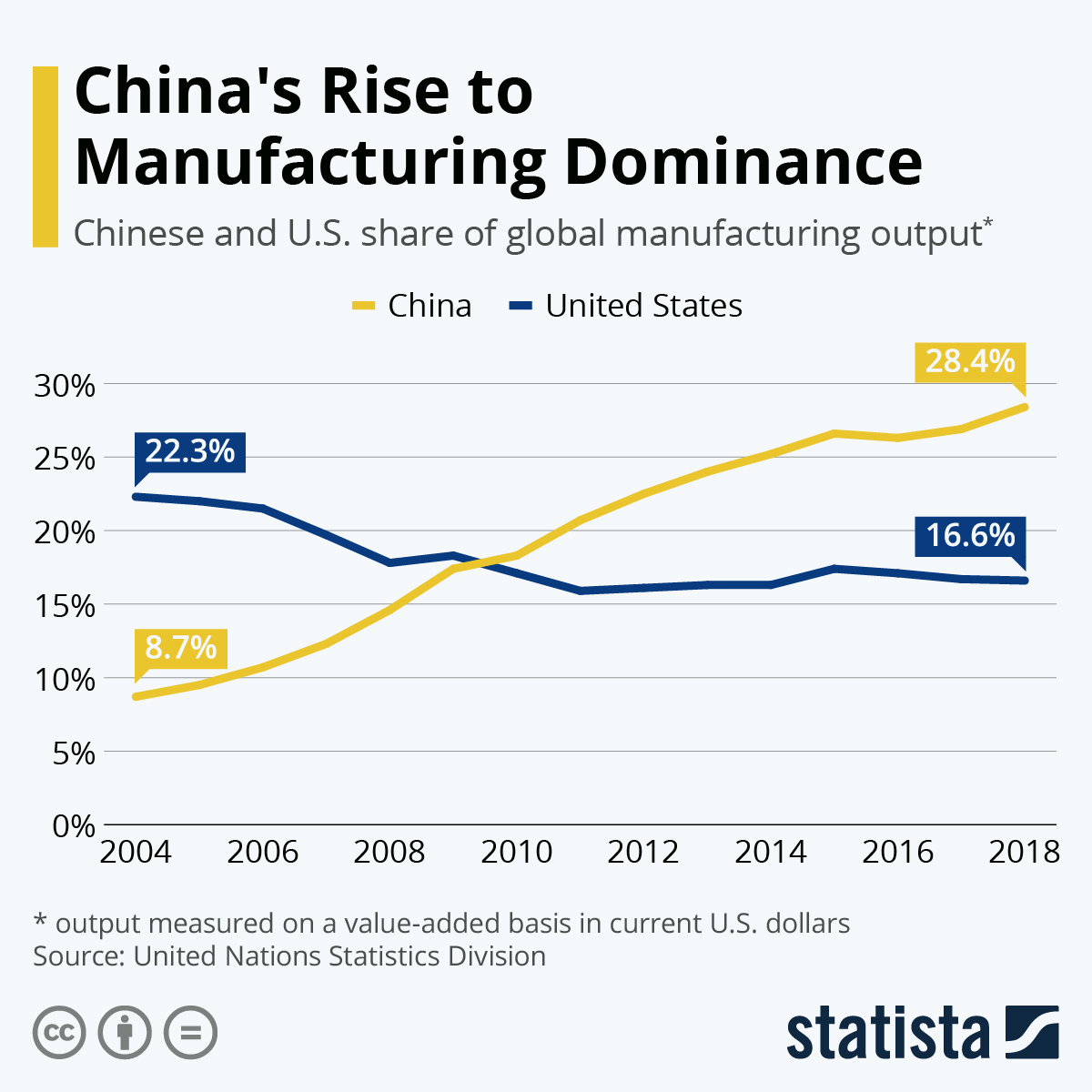

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you have a good understanding of the basics, you can identify potential sources of variation. It is important to identify whether the variations are random or systemic. Random variations happen when people make errors; systematic variations are caused externally. You could consider random variations if some widgets fall off the assembly lines. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. This could mean changing your approach or redesigning the entire process. Test them again once you've implemented the changes. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.