Industrial Engineering Jobs Houston

Industrial engineering jobs are plentiful in houston. These sought-after jobs come with a competitive income, a challenging environment to work in and plenty of opportunity for growth.

Jobs in industrial engineering for entry level professionals in Houston

This is the perfect entry-level role for anyone who wants to get their foot into the industry. This is an excellent way to get to know the company and its people.

This entry-level job offers you the chance to expand your knowledge and develop your skills by participating in the mentorship programme. The position offers a variety of benefits, including paid time-off, health insurance and flexible spending accounts. You can also take advantage of tuition assistance and 401K with a company match.

This is a great entry-level job that will pay you just enough to move out of your cubicle. This is a great opportunity to develop lasting relationships both with C&S and your colleagues.

The best thing is you'll get rewarded for all of your hardwork by a fantastic team. If you feel this would be a good fit for you, please apply!

ARCXIS offers inspection, design, and engineering services in residential construction to more than half of all states.

FAQ

What are the goods of logistics?

Logistics refers to all activities that involve moving goods from A to B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that the right product reaches the right place at the right time and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. Forecasting demand is one way to do this.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

What kind of jobs are there in logistics?

There are many types of jobs in logistics. Some examples are:

-

Warehouse workers – They load and unload pallets and trucks.

-

Transportation drivers – These drivers drive trucks and wagons to transport goods and pick up the goods.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers - They oversee the inventory of goods in warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators: They plan and manage logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers - These people fill orders based on what has been ordered.

-

Quality control inspectors (QCI) - They inspect all incoming and departing products for potential defects.

-

Others – There are many other types available in logistics. They include transport supervisors, cargo specialists and others.

Is it necessary to be familiar with Manufacturing Processes before we learn about Logistics.

No. It doesn't matter if you don't know anything about manufacturing before you learn about logistics. Understanding the manufacturing process will allow you to better understand logistics.

What does it take for a logistics enterprise to succeed?

It takes a lot of skills and knowledge to run a successful logistics business. You must have good communication skills to interact effectively with your clients and suppliers. It is important to be able to analyse data and draw conclusions. You must be able and able to handle stress situations and work under pressure. You must be creative and innovative to develop new ideas to improve efficiency. You must be a strong leader to motivate others and direct them to achieve organizational goals.

You should also be organized and efficient to meet tight deadlines.

How does manufacturing avoid bottlenecks in production?

Production bottlenecks can be avoided by ensuring that processes are running smoothly during the entire production process, starting with the receipt of an order and ending when the product ships.

This includes both planning for capacity and quality control.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It focuses on eliminating variation and creating consistency in your work.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to use lean manufacturing in the production of goods

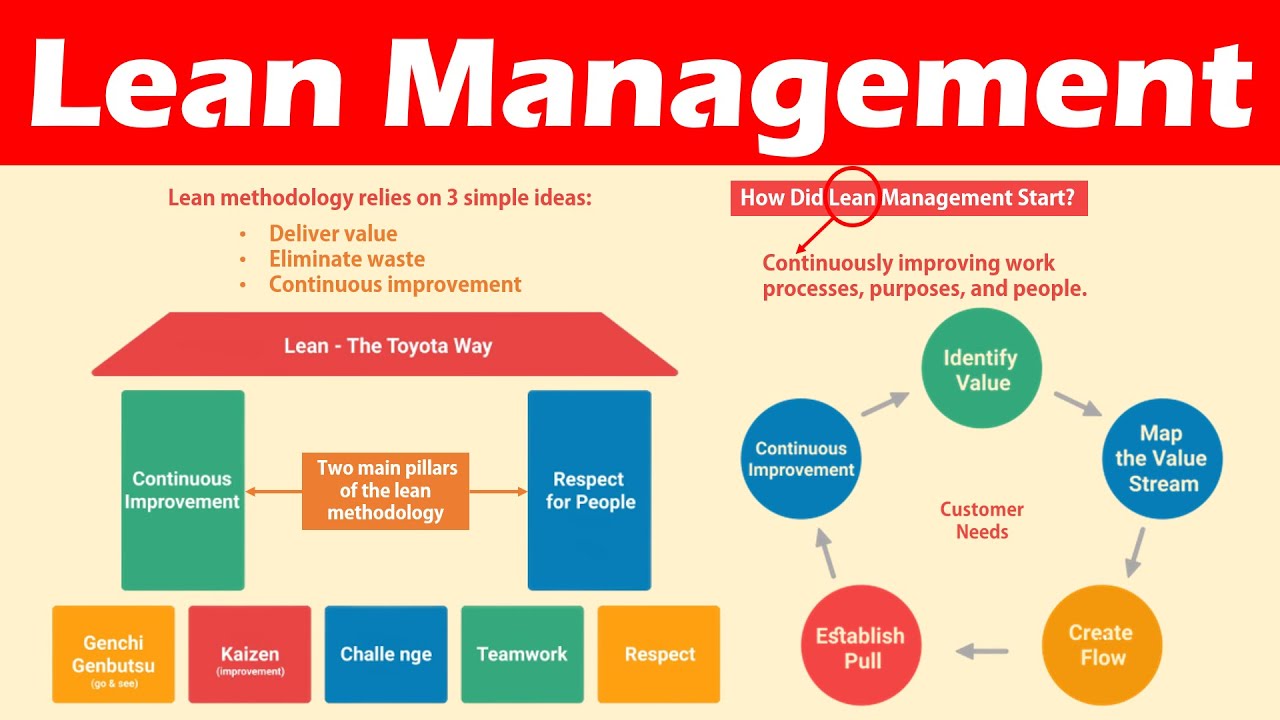

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

You can apply Lean Manufacturing to virtually any aspect of your organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three types of lean manufacturing.

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.