Train engineers are able to enjoy many perks in addition to a good pay. Train engineers make more than many people in their lifetime. It is expected that the demand for railroad transportation jobs will rise by approximately one percent. But, train engineer salaries can vary depending on where you are located and your years of experience. After many years in the industry, train engineers can earn well above $100,000 per annum.

Train engineers have a difficult job. First, federal licensing is required. Once you have your license, you will need some experience before you can work for yourself. To get your certification, you must pass a test. This test usually involves an eye exam and vision test. If you pass, you'll be qualified to work for federal railroads and other transportation agencies.

As a train engineer, you may spend long hours away from home. It is common to work nights or weekends. In addition, you may have irregular schedules, such as working on holidays or in the morning. You may also be exposed for different weather types. Sometimes, electric trains may be used, which can pose a challenge.

Also, you will need to pass a test which tests your mechanical skills. In general, locomotive engineers need to have good eyesight and hand-eye coordination, as well as be able to follow a schedule and operate controls efficiently. Sometimes, you might be asked to drive freight trains. This may mean that you will need to work nights and weekends.

Depending on where you are located, you may be required to work in the dark or be available for 24 hours per day. But as long as you can handle the job, it's a great way to make money. These large rail companies pay the best wages for train engineers. These companies have their own training program, but if they don't offer enough, you can be certified through a trade school.

You will also need a valid high school diploma, and a clean criminal conviction. Employers may appreciate a degree in train engineer, even though it isn't necessary. You can also study at a community or trade college to earn certification which will allow you get a job in train engineering.

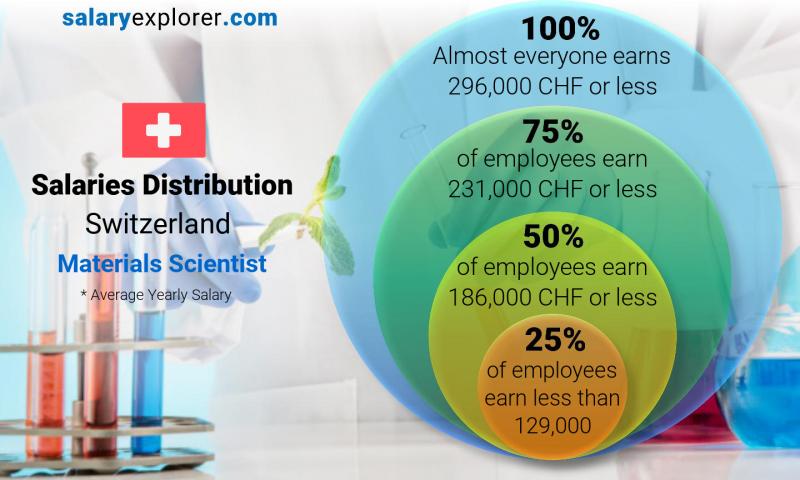

The average train engineer salary is around $5,254 a month. Your location, experience and employer can all impact your salary. The average salary for train engineers is $75,000 per annum. The highest earners can make $186,000 annually. You might even be able to get a higher salary than the average if you know where to look. Keep an eye out for openings in your area.

A higher degree could also increase your salary. Some locomotive engineers may go on as train trainers or railroad schedulers. Train engineers often find they love their work and will continue it for many years.

FAQ

Is it necessary to be familiar with Manufacturing Processes before we learn about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. Understanding the manufacturing process will allow you to better understand logistics.

What does "warehouse" mean?

A warehouse, or storage facility, is where goods are stored prior to being sold. It can be an indoor space or an outdoor area. In some cases it could be both indoors and outdoors.

What are my options for learning more about manufacturing

You can learn the most about manufacturing by getting involved in it. You can also read educational videos or take classes if this isn't possible.

What are the responsibilities of a logistic manager?

Logistics managers make sure all goods are delivered on schedule and without damage. This is done using his/her knowledge of the company's products. He/she should also ensure enough stock is available to meet demand.

What skills do production planners need?

Being a production planner is not easy. You need to be organized and flexible. You must also be able to communicate effectively with clients and colleagues.

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document ensures that everything is prepared and available when you are ready for shooting. This document should include information about how to achieve the best results on-set. This information includes locations, crew details and equipment requirements.

The first step is to outline what you want to film. You might have an idea of where you want to film, or you may have specific locations or sets in mind. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

After you have selected the car you want, you can begin to think about additional features. Do you have people who need to be seated in the front seat? You might also need someone to help you get around the back. Maybe you'd like to change the interior from black to a white color. These questions can help you decide the right look for your car. It is also worth considering the types of shots that you wish to take. What type of shots will you choose? Maybe you want the engine or the steering wheels to be shown. All of these things will help you identify the exact style of car you want to film.

Once you have established all the details, you can create a schedule. A schedule will tell you when you need to start shooting and when you need to finish. You will need to know when you have to be there, what time you have to leave and when your return home. It will help everyone know exactly what they have to do and when. If you need to hire extra staff, you can make sure you book them in advance. You should not hire anyone who doesn't show up because of your inaction.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects are quick and easy, while others take weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Shooting multiple takes over the same location will increase costs and take longer to complete. If you aren't sure whether you need multiple shots, it is best to take fewer photos than you would like.

Another important aspect of production planning is setting budgets. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. It is possible to reduce the budget at any time if you experience unexpected problems. But, don't underestimate how much money you'll spend. You'll end up with less money after paying for other things if the cost is underestimated.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

How can manufacturing prevent production bottlenecks?

To avoid production bottlenecks, ensure that all processes run smoothly from the moment you receive your order to the time the product ships.

This includes planning for capacity requirements as well as quality control measures.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It is focused on creating consistency and eliminating variation in your work.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If you notice a large deviation, then it is time to fix it.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you have a good understanding of the basics, you can identify potential sources of variation. You'll also want to determine whether these variations are random or systematic. Random variations happen when people make errors; systematic variations are caused externally. Random variations would include, for example, the failure of some widgets to fall from the assembly line. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you identify the problem areas, it is time to create solutions. That solution might involve changing the way you do things or redesigning the process altogether. After implementing the new changes, you should test them again to see if they worked. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.