China is second in terms of global economy, and it's a major force in manufacturing. In recent years, China has experienced a significant growth in its economy and is a major producer of many products. Around 33% is attributed to its industrial sector and it is by far the largest industry of the country.

China's Industrial Sector is one of fastest-growing sectors in the world. The growth has been primarily due to the shift away from SOEs and toward open-market-reforms. China began making these reforms in 1978. Since that time, the number of foreign companies and individual Chinese firms has increased dramatically.

By providing cheap loans, free land and low-interest capital, the Chinese government has supported the development of its industries. It allows them to compete in the marketplace and sell at lower rates than their rivals abroad.

These subsidies have been a major factor in China's past growth and prosperity. But in recent decades, the government's assistance has diminished and China is now dominated almost entirely by private enterprises.

The government no longer drives the Chinese economy. This has enabled a wider variety of businesses enter the market, and they have become an important part of China's growth.

China's productivity has also grown rapidly over the last few decades. This has led a lot of jobs to be created, especially in services.

China's manufacturing is a major industry, contributing nearly 46.8% to the total GDP. This is due in large part to the amount of money that Chinese have invested into their heavy industries.

There are a lot of industries that are important to China's economy and each one plays an important role in the way the country operates. This includes agriculture, energy and the manufacturing sector.

China's manufacturing industries are very important and have grown steadily in the last century. The country is now the largest producer in the entire world of cement, chemical fertilizers and steel.

China is also a leading exporter for cotton and textiles. China's cotton industry, which accounts for 10% of global production, is a vital part of China's economy.

Construction, mining, oil and gas are also important industries in China. These sectors are all important to the Chinese economy and provide employment for a large number of people.

The manufacturing industry plays a key role in China's overall economy. Find a manufacturer you can trust to help your company grow. Knowing what to look out for can make this process easier.

FAQ

What are the main products of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

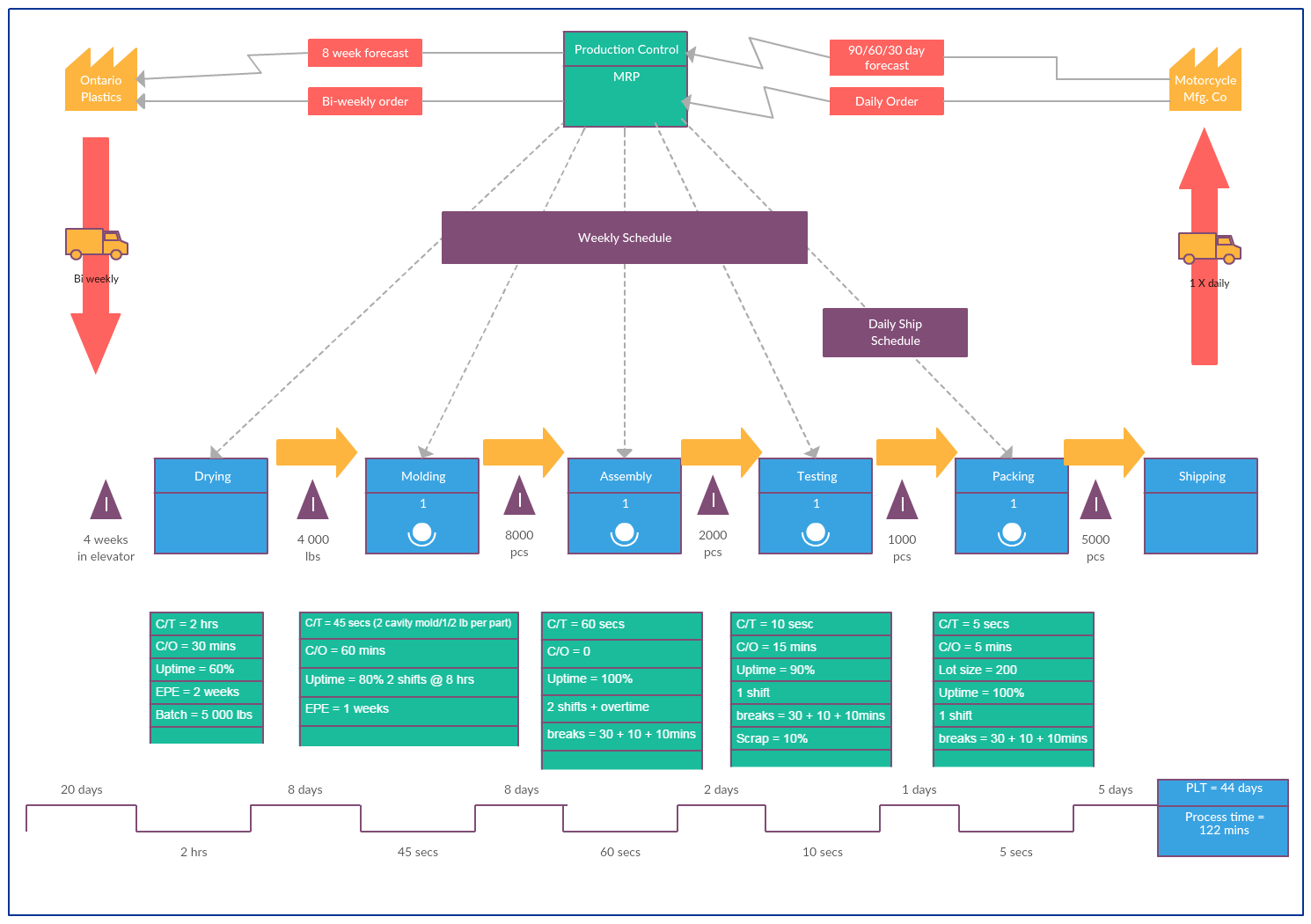

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

How can manufacturing excess production be decreased?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. This would allow us to use our resources for more productive tasks.

This can be done by using a Kanban system. A Kanban Board is a visual display that tracks work progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents an individual priority level.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. If a task is still in its beginning stages, it will continue to be so until it reaches the end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. With a Kanban board, managers can see exactly how much work is being done at any given moment. This data allows them adjust their workflow based upon real-time data.

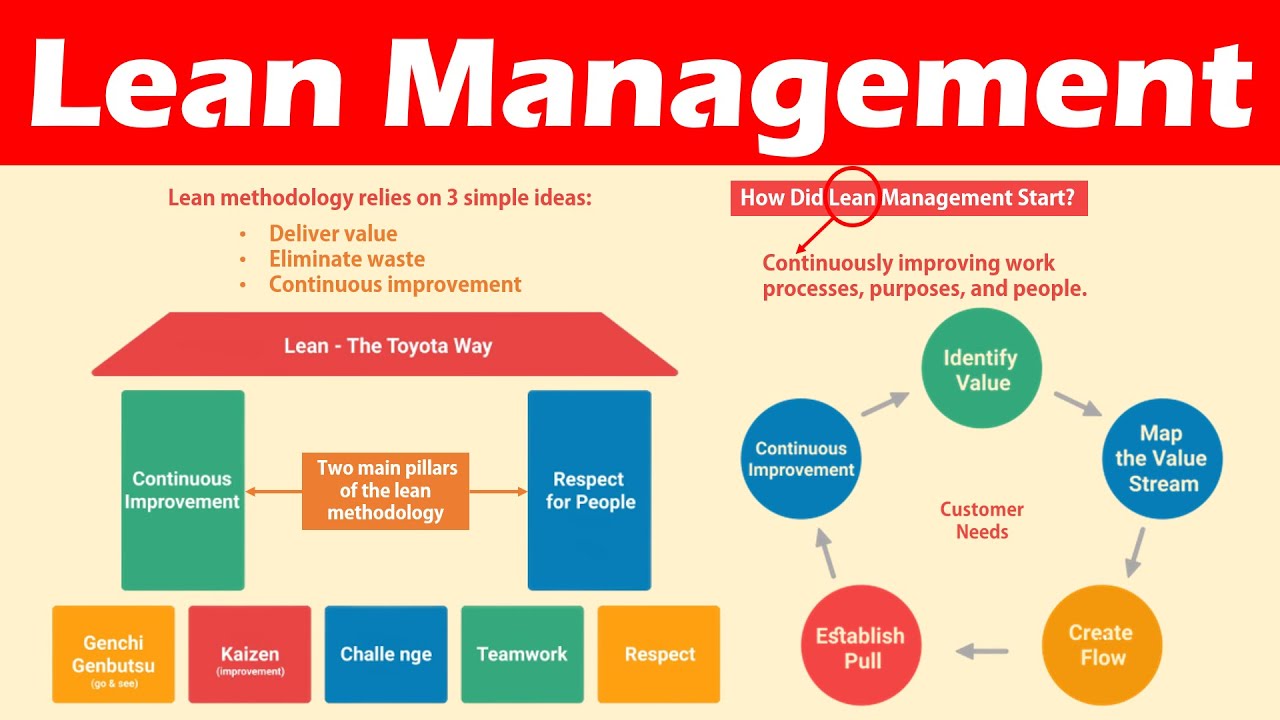

Lean manufacturing is another option to control inventory levels. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Any product that isn't adding value can be considered waste. The following are examples of common waste types:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

What type of jobs is there in logistics

Logistics can offer many different jobs. Some examples are:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers - These are responsible for overseeing the stock of goods in warehouses.

-

Sales representatives - They sell products to customers.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service representatives – They answer emails and phone calls from customers.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers - These people fill orders based on what has been ordered.

-

Quality control inspectors (QCI) - They inspect all incoming and departing products for potential defects.

-

Others – There are many other types available in logistics. They include transport supervisors, cargo specialists and others.

What is the role and responsibility of a Production Planner?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. They also ensure the quality of the product and service meets the client's requirements.

What are the 7 R's of logistics?

The acronym 7R's of Logistic is an acronym that stands for seven fundamental principles of logistics management. It was developed and published by the International Association of Business Logisticians in 2004 as part of the "Seven Principles of Logistics Management".

The acronym consists of the following letters:

-

Responsible - ensure that actions are in compliance with legal requirements and do not cause harm to others.

-

Reliable - have confidence in the ability to deliver on commitments made.

-

Reasonable - use resources efficiently and don't waste them.

-

Realistic – Consider all aspects, including cost-effectiveness as well as environmental impact.

-

Respectful – Treat others fairly and equitably.

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable - provide customers with value-added services.

What are the responsibilities of a logistic manager?

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is accomplished by using the experience and knowledge gained from working with company products. He/she also needs to ensure adequate stock to meet demand.

What is production plan?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. This document is designed to make sure everything is ready for when you're ready to shoot. This document should also include information on how to get the best result on set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

The first step is to outline what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you have selected the car you want, you can begin to think about additional features. Do you have people who need to be seated in the front seat? Perhaps you have someone who needs to be able to walk around the back of your car. You might want to change your interior color from black and white. These questions will help guide you in determining the ideal look and feel for your car. You can also think about the type of shots you want to get. Do you want to film close-ups, or wider angles? Maybe you want to show your engine or the steering wheel. These factors will help you determine which car style you want to film.

Once you have all the information, you are ready to create a plan. You can create a schedule that will outline when you must start and finish your shoots. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. It will help everyone know exactly what they have to do and when. Hire extra staff by booking them ahead of time. It's not worth paying someone to show up if you haven't told him.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects are quick and easy, while others take weeks. When creating your schedule, be aware of whether you need more shots per day. Multiple takes of the same location will lead to higher costs and take more time. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Budgeting is another important aspect of production planning. It is important to set a realistic budget so you can work within your budget. Remember that you can always reduce the budget later on if you run into unforeseen problems. However, you shouldn't overestimate the amount of money you will spend. You will end up spending less money if you underestimate the cost of something.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma's primary goal is to reduce variation from the average value of production. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If this deviation is too big, you know something needs fixing.

Understanding how variability works in your company is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. It is important to identify whether the variations are random or systemic. Random variations are caused by human errors. Systematic variations can be caused by outside factors. You could consider random variations if some widgets fall off the assembly lines. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you identify the problem areas, it is time to create solutions. You might need to change the way you work or completely redesign the process. To verify that the changes have worked, you need to test them again. If they don't work you need to rework them and come up a better plan.